Your Trusted Partner in Advanced Processing Equipment & Turnkey Solutions

RIBBON BLENDER :- The Ribbon Blender comprises of a U-shaped horizontal trough, specially designed Double Helical Ribbon Agitator, rigid fabricated structure motor, gear box. It is light duty blenders, useful for easy mixing powder components it is a LOW SHEAR Mixer, most commonly used for SOLID/SOLID, SOLID/LIQUID Mixing and when high shearing force is not required. Its counter flow helicoid flight mounted on shaft ensuring gentle mixing. Blades are designed for triple action mixing to suit product end characteristics. It also occupies less head room space for large volume mixing. It is used for uniformly dry mixing and blending applications in the pharmaceutical, chemical, cosmetic, food, pesticides, detergents, and plastics industries.

VERTICAL RIBBON BLENDER :- Vertical Ribbon Blenders are able to give perfect result of mixing due to the design of an outer spiral type mixing element with an inner screw, rotating together in a conical shape trough, which provides a multi-dimensional movement of the materials, and a complete discharge of all the mixed material without any residue. The Vertical Ribbon Mixers are also featured with no contamination to the product, due to the fact that the shaft sealing is above the working area, thus no contact with the product.

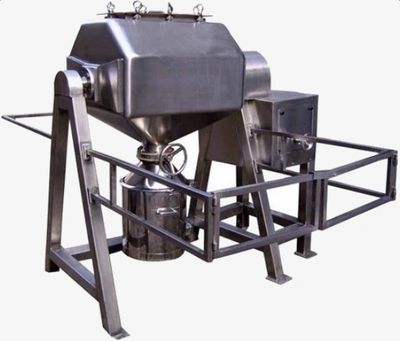

V-BLENDER :- ‘V’ Blender is an intensive mixing system designed specially to handle ordered dry mixing of excipients such as cohesive as well as adhesive powder. This rotating shell V-type blender with no packing glands around the shafts entering the chamber ensure total elimination of cross contamination. The special design ensures minimal attrition when blending fragile granules and is suitable for Pharmaceutical, Nutraceutical, Food & Cosmetic industries.

DOUBLE CONE BLENDER :- The main body of the blender consists of two cone-shaped sections welded at their bases to a central cylindrical section. The axis of rotation is perpendicular to the cone axis and passes through the cylindrical section. The driving motor is located at one of the two lateral supports holding the blender body. The double cone blender is used to produce homogeneous solid-solid mixture. Mixing is a common process step in the manufacture of products for industries such as healthcare, food, chemical, cosmetics, detergents, fertilizers and plastics. The mixture is discharged through a hermetically closing butterfly valve which can be operated manually or automatically.

OCTAGONAL BLENDER :- Octagonal Blender, due to its octagonal shape is designed to process larger volume of material. It occupies less space compared to other similar blenders like 'V' and Double Cone. Power consumption is also less. The blending takes place at low speed during operation. It is well balanced even in higher capacities. It is very useful for pharmaceutical industries wherein gentle blending of dry granules of powder is to be done. It is a slow speed blender and has removable type baffles mounted on a rectangular shell. The important feature of the machine is easy to wash in place. Octagonal blender is supplied with a bin charging system or can be designed for vacuum charging. Dust free charging system is also incorporated, which is a completely closed system for charging and discharging of powders or granules.

VIBRO SHIFTER :- Vibro separators are circular unitary gyratory screens used to separate mass composition of solids from solids,liquid from solid and for gradation of materials as per particle size, having a very wide range applications. This is accomplished by vibrating the screens in three different planes along the vertical axis by means of a specially designed vibratory motor having off centred weights at the top and bottom end of the motor shaft. The top weight causes vibration in the horizontal plane which causes the material to move across the screen towards the periphery. The lower weight acts to tilt the machine which causes vibration in the vertical tangential axis.

SCREW CONVEYOR :- Screw conveyors are a useful and pretty simple material handling tool for transporting bulk materials to a uniform or sloppy plane. One of their primary jobs is breaking any chunks in the material. They are used to convey various types of material. Be it dry, coarse, sluggish, thick, liquid, a screw conveyor can deal with them without a glitch. The materials are moved in a set quantity from the entrance till its way out. At the inlet, materials are organized based on the size and strength of the conveyor.

Screw conveyors are most popular in the bulk material handling industry to shift bulk materials between different points at a controlled and even rate. In several manufacturing industries, ordinary filters, jet pulse filters, or dust collectors are used to gather the dust from production chains. Here, screw conveyors play an essential role in removing the accumulated dirt. In some of the major industries, screw conveyors are used for processes like feeding, mixing, batching, and grinding. Screw conveyors are used in the agriculture industry in the form of agricultural tools like threshers and balers.

ROTARY DRUM BLENDER :- The Rotary Drum Mixer is a quick, efficient, and the ideal gentle industrial mixer with a low speed and no moving parts inside the drum. Rotary drum mixers are used all over the world for Tea Blending, Detergent Powder Blending, Seeds Blending and Fertilizers often with optional spray bar for liquid additions. The unique mixing blades are fully welded to the rotating drum and completely fluidise the mixture with every revolution, the combination of low speed and no moving parts within the drum mixer produce a no shear, gentle mixing action. Within the fluidised mixture powders and granules of widely different bulk densities and particle size can move freely ensuring a rapid and efficient mix.